A next-generation fertiliser created in a partnership between Manildra Group, Queensland universities and State Government is planned to shake up an industry blamed for substantial damage to the Great Barrier Reef and increasing farming costs.

Fertiliser inefficiencies result in an estimated 80,000 tonnes of nitrogen entering the Great Barrier Reef, causing damage to coral and seagrasses, and hindering an expanding agro-technology sector.

“We’re hoping to create a commercially viable next-generation fertiliser specifically targeted for Australia’s sugar industry, where the current market fertilisers are inefficient and costly,” said Manildra Group Technical Manager Mark Baczynski.

The major component of the controlled-release fertiliser will be technologically advanced wheat-based starch, produced as part of a fully integrated manufacturing process at Manildra Group’s state-of-the-art Shoalhaven Starches manufacturing facility in Nowra, NSW.

“We’re hoping this will complement our paddock-to-plate production process, by further value-adding to wheat through our creation of an environmentally-responsive bio-composite fertiliser based on starch,” said Mr Baczynski.

“The time-release formulation of the wheat starch in the fertiliser will be responsive to differing soils, temperatures and the environment – breaking down to reduce reef run-off.

“It’s a win-win situation if we can effectively match crop demand whilst increasing efficiencies for farmers and yield great environmental benefits for the Great Barrier Reef.”

The three-year joint project between Manildra Group, University of Queensland, James Cook University and the Queensland Department of Agriculture and Fisheries received financial support from the State Government’s Advance Queensland Industry Partnership program.

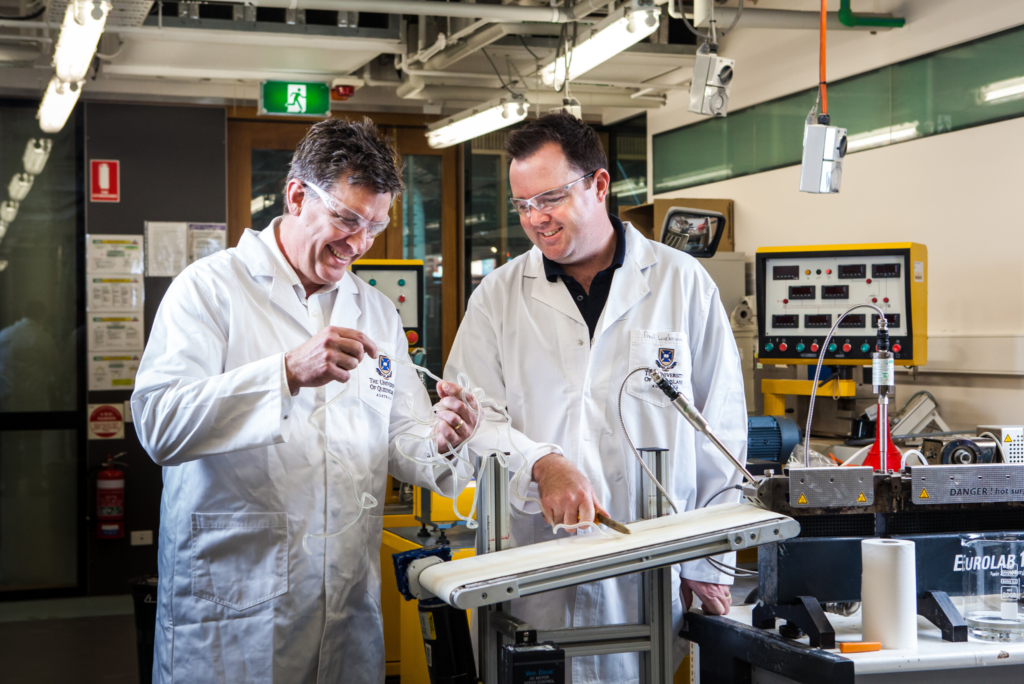

UQ School of Chemical Engineering Research Fellow, Dr Paul Luckman, said that with minimal innovation in the fertiliser space, their aim was to create fully biodegradable material that slows the release of fertiliser to match the take-up rate by a plant.

“We won’t have the issue of excess nutrients drifting around in the soil because nitrogen is released from the fertiliser when required and the crop takes it up. This prevents nutrient loss from farm soil,” said Dr Luckman.

“Fertilisers as they are now are only about 50 per cent efficient at supplying crops with what they need, and much of what is applied to the crop is lost to waterways and into the atmosphere. Maintaining that oversupply is a massive unnecessary cost to farmers.

“At the same time, our natural systems and food chains are being overwhelmed – fertilisers entering the water are fuelling algal blooms, which start the cascade of problems that we see threatening our reef and estuary life.”

Dr Luckman said Manildra Group’s expertise in starch and agriculture, and the company’s close association with Australian producers and end-users, had been critical to the project.

“As a strong agricultural and manufacturing industry partner and expert in modified starches, Manildra Group and our partners can build a more high-yielding and highly efficient agriculture industry,” said Dr Luckman.

“Manildra Group is one of the biggest producers of materials for this project, and we’re excited to see the environmentally responsive fertiliser formulation concept come to fruition.”